Naval Surface Ship Design

Optimization for Affordability

PHASE

I

Grant: N00014-02-1-0796

Sponsor: Katherine Drew, ONR 334, Office of Naval

Research

Dr. Alan Brown and Dr. Wayne Neu, Virginia Tech

Project

Theses and Reports

Project

Papers

Design

Projects

Motivation and Overview

Naval ship concept design is

traditionally an “ad hoc” process.

Selection of design concepts for assessment is guided primarily by

experience, design lanes, rules-of-thumb and imagination. Communication and coordination between design

disciplines (hull form, structures, resistance, etc.) requires significant

designer involvement and effort. Concept

studies continue until resources or time run out. Critical elements missing from this process

are:

·

A consistent format and methodology for multi-objective decisions based

on dissimilar objective attributes: specifically effectiveness, cost and

risk. Mission effectiveness, cost and

risk cannot logically be combined as in commercial decisions where discounted

cost can usually serve as a suitable single objective. Multiple objectives must be presented

separately, but simultaneously, in a manageable format for trade-off and decision

making.

·

An efficient and robust method to search the design space for optimal

concepts.

·

Practical and quantitative methods for measuring effectiveness. An Overall Measure of Effectiveness (OMOE)

model or function is an essential prerequisite for optimization and design

trade-off. This effectiveness can be

limited to individual ship missions or extend to missions within a task group

or larger context.

·

Practical and quantitative methods for measuring risk. Overall risk includes schedule, production,

technology performance and cost factors. It is measured using an Overall

Measure of Risk (OMOR).

·

An effective framework for transitioning and refining concept

development in a multidisciplinary design optimization (MDO).

·

A means of using the results of first-principle analysis codes at

earlier stages of design.

This project develops a

process, tools and models implemented in Model Center, a general purpose design

environment and optimization program, to address these critical elements. Steps

in this process are:

1. Concept Exploration. A

multi-objective genetic optimization (MOGO) considers discrete major system

decisions and top level requirements including payload, choice of propulsion

system and power, range and speed, parent hull forms, hull materials, arrangement,

and manning. Genetic algorithms (GAs)

are able to explore a design space that is very non-linear, discontinuous, and

bounded by a variety of constraints and thresholds. These attributes prevent application of

mature gradient-based optimization techniques including Lagrange multipliers,

steepest ascent methods, linear programming, non-linear programming and dynamic

programming. GAs are also ideally-suited

for multi-objective optimization since they develop a population of designs

vice a single optimum. This population

can be forced to spread-out over a non-dominated frontier of design

alternatives as illustrated in Figure 1. A non-dominated solution, for a given

problem and constraints, is a feasible solution for which no other feasible

solution exists that is better in one attribute and at least as good in all

others. The non-dominated frontier is

the first product of this process.

Figure

1 - Two Objective Attribute Space

2. Customer selection of preferred design(s). There is no reason to pay more for the same

effectiveness or accept less effectiveness for the same cost. Preferred designs must always be on the

non-dominated frontier. The selection of

a particular non-dominated design depends on the decision-maker’s preference

for cost, effectiveness and risk. This

preference may be affected by the shape of the frontier and cannot be

rationally determined a priori. When

considering three attributes, the non-dominated frontier is a surface. Points on this surface represent feasible

ships, and can be mapped to specific design parameters. With such a surface, the full range of

cost-risk-effectiveness possibilities can be presented to decision-makers,

trade-off decisions can be made, and specific concepts can be chosen for

further analysis. “Knees in the curve” can be seen graphically. "Knees" are significant changes in

the slope of the frontier. It is often

desirable to be at the top of a high effectiveness to cost slope. Up to this point a little more cost will buy

a lot more effectiveness. Beyond it, the

cost of more effectiveness is much higher.

3. Concept Development. Starting

from selected concepts from Step 2, this step develops the selected concept

designs in a multidisciplinary design optimization (MDO) using mission

effectiveness, cost, risk or some weighted combination of these as a

single-objective attribute. Appropriate

constraints on effectiveness, cost and risk are included. Discrete design and requirement decisions

made in Step 2 become bounds and constraints in Step 3. This allows the application of more

traditional and efficient optimization methods.

Deliverables [1] through [9]

detail the research accomplished in Phase 1 of this project, based on the 3-step

process outlined above.

Phase 1 Progress

- Complete

Task 1.0 Literature, Information and Data Search – Literature and data searches

were completed for the following topics: 1) Overall Measure of Effectiveness (OMOE)

and AHP validation [4]; 2) Risk approaches to naval ship design [1]; and 3)

Methods for design with uncertainty [1,2,3,5]. Reference lists and summaries

are included in these related theses.

Task 2.0

Multi-Objective Models and Probabilistic Design Optimization

Task 2.1 OMOE Model - A simplified methodology

was developed for building an Overall Measure of Effectiveness (OMOE) model

using the Analytical Hierarchy Process and Multi-Objective Value Theory [4,6].

A validation experiment was completed using the war-gaming software HARPOON3

[4], Figure 2. In this validation, ten student experts were

“educated” in a series of war-gaming experiences. OMOE functions were developed

using the OMOE methodology and expert opinion. The OMOE functions were then

used to rank a series of surface combatant designs. This ranking is compared to

the ranking results from a direct war-gaming comparison of the designs.

Figure 2 - Harpoon 3

Workspace

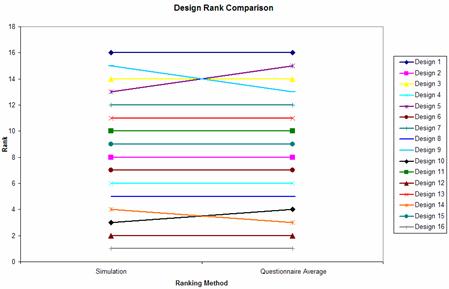

Figure 3 – Simulation Rank vs. Questionnaire Average Rank

An OMOE calculation using questionnaire averages most

closely matched and provided a good prediction of direct simulation results, Figure 3.

Task 2.2 Cost Model - Engineering cost models must be reliable, practical

and sensitive to the cost and performance impact of producibility enhancements. A

baseline surface combatant cost model was developed using a modified weight-based approach [4]. A more flexible model

will be developed in Phase 2 using ACEIT (Automated Cost Estimating Integrated

Tools). ACEIT is an automated architecture and framework for cost estimating.

It is a government-developed tool that has been used to standardize and

simplify the Life Cycle Cost estimating process in the government environment.

Core features include a database to store technical and (normalized) cost data,

a statistical package specifically tailored to facilitate cost estimating

relationship (CER) development and a spreadsheet that promotes structured,

systematic model development, and built-in government-approved inflation,

learning, time phasing, documentation, sensitivity/what-if, risk and other

analysis capabilities. Our task will be to adapt this general framework for

concept development naval ship cost analysis including producibility. Cost

uncertainty aspects will be integrated with Task 2.3.

Task 2.3 Risk and Uncertainty - The

DoD Risk Management Guide requires risk assessment of acquisition performance,

cost and schedule through the identification, subsequent analysis and

prioritization of adverse program events based on their probability of

occurrence and consequences. This type of risk assessment is very important in

concept exploration and design when considering new technologies, unique

processes and novel concepts. Uncertainty associated with the design process

itself and the definition and selection of specific design alternatives can

also have a significant impact on performance, cost and schedule risk.

Inherent, statistical and modeling uncertainty, and uncertainty due to human

error, must be considered in the design process, but uncertainty analysis

requires a more detailed and computationally intensive probabilistic approach.

It is most appropriate for post-exploration design optimization, after specific

cost and performance goals and thresholds have been set, to maximize the

probability of achieving these goals.

We have adopted a two-stage concept

design strategy that uses a multi-objective optimization and simplified risk event

approach for concept exploration, and a more rigorous multi-disciplinary

optimization with uncertainty for concept development. Concept exploration

identifies non-dominated design concepts and establishes the optimum

relationship between effectiveness, cost and risk given a broad selection of

technologies and design alternatives. Risk is defined using a separate

objective attribute, an Overall Measure of Risk (OMOR), which specifically

addresses the high-risk events associated with the selection of new technologies,

processes and concepts. With this perspective, decision-makers may establish

rational requirements, select technologies, narrow the design space, and

establish a non-dominated concept baseline design or set of designs. Once these

early decisions are made, concept development and the remaining design phases

add detail, refine requirements and reduce risk. Optimization continues into

concept development using uncertainty analysis with Confidence of Success (CoS)

as the third objective attribute. Tim Mierzwicki (MS Ocean Engineering 2003)

performed the initial risk and uncertainty literature search, developed the

OMOR approach, and performed an initial OMOR case study [1,7]

Since the mid 1990’s, Mavris

and associates at Georgia Tech have been exploring robust design techniques in

the presence of parameter uncertainties accounted for by assigning probability

distributions to selected model inputs.

The output responses have been generated by Monte Carlo simulations

performed either using the full model or a response surface approximation of

its output. They have also had success

using the Advanced Mean Value (AMV) method for calculating the cumulative

distribution function (CDF) of the model response in aerospace

multidisciplinary design applications.

The AMV method has the virtue of requiring far fewer model runs than

does a Monte Carlo simulation. It is one

of several Fast Probability Integration methods developed by Southwest Research

Institute and NASA Lewis Research Center.

The primary difference in our initial

research is that we are concentrating on the uncertainty generated from the

analysis process, the modeling uncertainty. For now, we assume the input

variables to be deterministic with randomness coming only from the embedded

uncertainties in the analyses.

Because of the

multidisciplinary nature of a ship synthesis model, perturbations introduced in

one analysis are carried forward to perturb the next and then on to the next

and so on. To further complicate the

issue, ship synthesis models typically require multiple iterations to balance

the design. Each subsequent level of

analysis may introduce its own uncertainty and inherit uncertainty from

previous analyses. It is difficult to

characterize this cascading of uncertainty through a highly nonlinear analysis.

We have examined several

methods to obtain information on the output distributions more efficiently than

through the Monte Carlo simulation. The

family of variance reduction techniques described, for example, by Law and

Kelton, are designed to obtain this information in a statistically efficient

manner. Statistical efficiency deals

with the precision of an estimator. If we are trying to describe an output

random variable (say the cost of a design), we are interested in certain

parameters that define its distribution; for example its mean and standard

deviation.

We used the Advanced Mean Value method to determine

statistics of the, now random, ship design characteristics that are calculated

by our model. We then determined

probabilities that a given design will have greater than any given level of

OMOE or the probability that the cost will be less than some level. We can also determine the probability that

the design will be feasible, i.e., it meets all the applicable

constraints.

The confidence of success is the joint probability

that a given design 1) is feasible, 2) that it will have a cost that is less

than a given maximum cost and 3) that it will have an OMOE that is greater than

a given required value. This confidence

of success (CoS) can be treated as a third objective function in a genetic

algorithm based optimization. Figure 4 is a three-dimensional Pareto frontier from which a

ship designer can pick the design of his choice considering both the overall

value of the design and the risk being taken at that point in the design

space.

This work was performed

primarily by Sandipan Ganguly (MS Ocean Engineering, 2002) and Emanuel Klasen

[5].

Figure 4 – Non-Dominated

(Pareto) Frontier with Confidence of Success

Task 2.4

Design Test Cases and Applications - The

approach, methods and tools developed in Phase 1 were exercised in a number of

case studies using a simple ship synthesis model [4,5,6,8,9], and the US Navy’s

Advanced Ship Synthesis and Evaluation Tool (ASSET) [2,3] in the ModelCenter

(MC) design environment. The simplified model case studies were performed

primarily by undergraduate ocean engineering students. A Mixed-Language

Programming (MLP) approach was used to interface with the ASSET software.

Component-based software construction has gained significant momentum

and become a main focus of software engineering research and computing. Even

though there are many standards available now for developing component-based

applications, there are still applications where a single-language based

approach is not suitable. Some of the actions that a program performs are best

expressed in a particular language, and the choice of a programming language is

strongly dictated by the programmer’s preference. The Mixed-Language

Programming (MLP) approach was used to build component-based software systems,

with a specific emphasis on the ship design problem [3]. This approach was

compared with a newer tool-based integration methodology of modeling and

building component-based software applications, using tools such as Phoenix

Integration’s ModelCenter and Analysis Server.

ModelCenter and ASSET were also applied to two ship design case

studies, LHA(R), a replacement for the US Navy amphibious assault ship, and

DDG-51, a destroyer class vessel [2,5]. Overall Measure of Effectiveness (OMOE)

and lead ship acquisition cost were the objective attributes. Design

feasibility was evaluated, and various ship parameter calculations were

performed using ASSET. ASSET was integrated with the design optimization

software DARWIN to obtain the non-dominated frontier over a range of acquisition

cost, Figure

5. Model Center software was used to integrate ASSET

and Darwin, Figure

6. VBScript components were used to run various ASSET

modules, apply the trade study option configurations, and calculate the

objective functions. Windows script components were developed to access the

operating system and invoke ASSET.

Figure

5 – LHAR

Non–Dominated Frontier

Figure

6 – DDG-51 ASSET

Model in Model Center

Students Working

on the Project

- Sandipan Ganguly – Uncertainty - MS Ocean Engineering 2002

- Ben Young – OMOE – MS Ocean Engineering 2003

- Tim Mierzwicki – Risk (OMOR) – MS Ocean Engineering 2003

- Murali Krishnan Gunasekaran

– System Architecture and Uncertainty – MS Computer Systems 2004

- Swaroop

Neti – MDO Application with ASSET – MS Ocean Engineering 2005

- Daniel Demko – OMOE – MS Ocean Engineering 2005

- Emanuel Klasen – Uncertainty – Visiting Scholar

- Nathan Good –

Uncertainty (MS ongoing)

Conclusions

Phase

1 of this project accomplished the following objectives:

- Developed a practical

and rational concept exploration process and tools that search ship design

space using a multi-objective genetic optimization (MOGO).

- Developed and

validated a method to create an Overall Measure of Effectiveness (OMOE)

for a particular ship design.

- Developed a method to

create an Overall Measure of Risk (OMOR) for a particular ship design.

- Developed tools to

perform Multi-Disciplinary ship optimization using ASSET, MAESTRO and

various system architectures interfacing with Model Center.

- Conducted preliminary

investigations into related uncertainty techniques.

- Completed a series of

practical case studies demonstrating these methods and tools.

Phase 2 Plan

Phase 2 will include more Response

Surface Modeling (RSM), a more detailed Design of Experiments (DOE) and

variable screening, and capabilities for more physics-based modeling and

assessing the impact of new technologies. We would like to focus on multi-hull

high speed ships, and on using the computationally intensive tools required for

these ships including a Rankine panel method code for seakeeping and wave

resistance, an extensive dynamic simulation for machinery system definition and

performance, a structural finite element code and codes for accessing

structural vulnerability and survivability. We will also continue uncertainty

modeling and solution development in increasingly complex and realistic

problems with more demanding requirements for computational efficiency. Phase 2

will also include work on a surface ship manning model and submarine

applications.

Project Deliverables

[1] Mierzwicki, T. (2003), “Risk Index for

Multi-Objective Design Optimization of Naval Ships”, MS Thesis, Department

of Aerospace and Ocean Engineering, Virginia Tech, April 24, 2003.

[2] Neti, S.N. (2005), “Ship Design Optimization Using

ASSET”, MS Thesis, Department of Aerospace and Ocean Engineering, Virginia

Tech, February 10, 2005.

[3] Gunasekaran, Murali Krishnan (2003),

“Component-Based

Application Development Using a Mixed-Language Programming (MLP) Approach”,

MS Thesis, Department of Computer Science, Virginia Tech, December 2003.

[4] Demko, D. (2005), “Tools for Multi-Objective and

Multi-Disciplinary Optimization in Naval Ship Design”, MS Thesis,

Department of Aerospace and Ocean Engineering, Virginia Tech, May 2005.

[5] Klasen, E. (2006), “Confidence of

Success in Multi-Criteria Optimization of Multi-Disciplinary Ship Design Models”,

Report, Department of Aerospace and Ocean Engineering, Virginia Tech,

March 2006.

[6] Brown, A.J., Salcedo, J. (2003), "Multiple Objective Genetic Optimization In Naval Ship Design",

Naval Engineers Journal, Vol. 115, No. 4, pp. 49-61.

[7] Mierzwicki, T., Brown, A.J. (2004), “Risk Metric for Multi-Objective Design of Naval Ships”, Naval Engineers Journal, Vol. 116, No.

2, pp. 55-71.

[8] Good, N., Brown, A.J. (2006), “Multi-Objective Concept Design of an Advanced

Logistics Delivery Ship”, to be presented at ASNE Joint Sea Basing

Symposium, March 2006,

[9] Stepanchick, J., Brown, A.J. (2006),

“Revisiting

DDGX/DDG-51 Concept Exploration”, to be presented at ASNE Day, June 19-20,

2006, Arlington, VA.